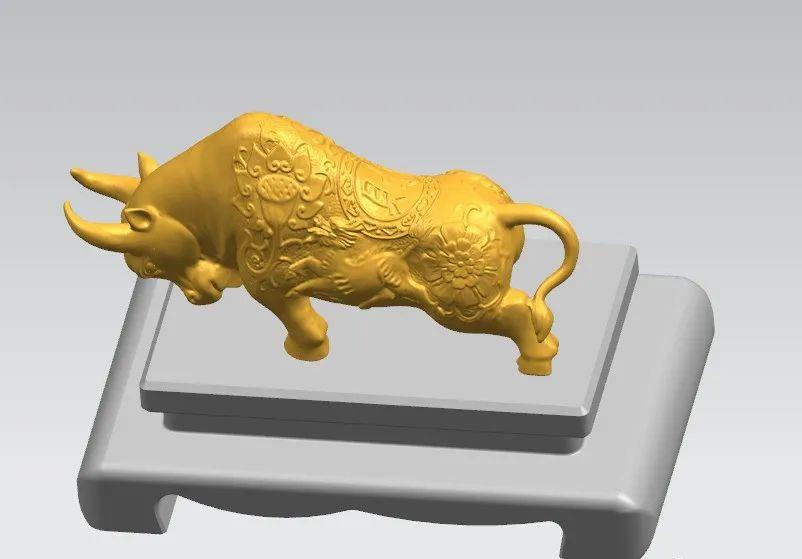

Kupanga makina a CNC kumaphatikizapo kugwiritsa ntchito makina owongolera manambala apakompyuta (CNC) kupanga ndikusintha kachidutswa kakang'ono, kapena chogwirira ntchito, pochotsa zinthu zokha.Kawirikawiri, zinthu zomwe zimagwiritsidwa ntchito ndi pulasitiki kapena zitsulo, ndipo pamene kuchotsa kwatha, chinthu chomalizidwacho chimapangidwa.

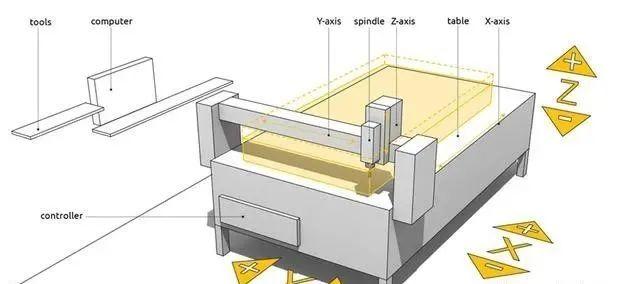

Njirayi imadziwikanso kuti subtractive kupanga.Pamakina a CNC, pulogalamu yamakompyuta imagwiritsidwa ntchito kuwongolera kayendedwe ka chida cha makina.

Mitundu yawamba CNC makina zida

CNC Machining njira monga ambiri mphero ndi kutembenukira, kenako akupera, magetsi kumaliseche Machining, etc.

Kugaya

Kugaya ndikugwiritsa ntchito chida chozungulira pamalo ogwirira ntchito, choyenda motsatira nkhwangwa 3, 4 kapena 5.Kugaya kwenikweni ndiko kudula kapena kudula kwa zida zogwirira ntchito, kulola ma geometri ovuta ndi magawo olondola kuti apangidwe mwachangu kuchokera kuzitsulo kapena thermoplastics.

Kutembenuka

Kutembenuza ndiko kugwiritsa ntchito lathe kupanga mbali zomwe zimakhala ndi ma cylindrical.Chogwirira ntchito chimazungulira pamtengo ndikulumikizana ndi chida chosinthira molondola kuti chipange m'mphepete, ma radial ndi axial mabowo, grooves ndi grooves.

Ubwino wa CNC Machining

Poyerekeza ndi makina achikhalidwe, makina a CNC amathamanga kwambiri.Malingana ngati kachidindo ka makompyuta ndi kolondola komanso kogwirizana ndi kapangidwe kake, chinthu chomalizidwacho chimakhala ndi zolondola kwambiri komanso zolakwika zazing'ono.

Kupanga kwa CNC ndi njira yabwino yopangira ma prototyping mwachangu.Itha kugwiritsidwanso ntchito popanga zinthu zomwe zimagwiritsidwa ntchito pomaliza ndi zigawo zake, koma nthawi zambiri zimakhala zotsika mtengo pakupanga kwanthawi yochepa.

Multi-axis CNC Machining

CNC mphero imaphatikizapo kuchotsa zinthu pogwiritsa ntchito zida zozungulira.Mwina chogwiriracho chimakhalabe choyima ndipo chidacho chimasunthira pa chogwiriracho, kapena chogwiriracho chimalowa mu makinawo pamakona okonzedweratu.Makina akakhala ndi nkhwangwa zambiri, m'pamenenso kupanga kwake kumakhala kovuta komanso kofulumira.

3-olamulira CNC Machining

Atatu-olamulira CNC mphero akadali mmodzi wa anthu otchuka ndi ambiri ntchito Machining njira.Pamakina a 3-axis, chogwiriracho chimakhala chokhazikika ndipo chida chozungulira chimadula motsatira nkhwangwa za x, y, ndi z.Ichi ndi njira yosavuta ya CNC Machining yomwe imapanga zinthu zokhala ndi zosavuta.Sikoyenera kupanga ma geometries ovuta kapena zinthu zomwe zili ndi zigawo zovuta.

Popeza nkhwangwa zitatu zokha zimatha kudulidwa, makina amathanso kuchedwa kuposa ma CNC anayi kapena asanu, popeza chogwiriracho chingafunikire kukhazikitsidwanso pamanja kuti mupeze mawonekedwe omwe mukufuna.

4-olamulira CNC Machining

Mu mphero zinayi za CNC, mphero yachinayi imawonjezeredwa kukuyenda kwa chida chodulira, kulola kuzungulira kuzungulira x-axis.Tsopano pali nkhwangwa zinayi - x-axis, y-axis, z-axis ndi a-axis (kuzungulira mozungulira x-axis).Makina ambiri a 4-axis CNC amalolanso chogwirira ntchito kuti chizizungulira, chomwe chimatchedwa b-axis, kuti makinawo azigwira ntchito ngati makina ophera komanso lathe.

4-axis CNC Machining ndi njira yopitira ngati mukufuna kubowola mabowo kumbali ya chidutswa kapena pamwamba pa silinda.Imafulumizitsa kwambiri njira yopangira makina ndipo imakhala ndi kulondola kwakukulu kwa makina.

5-olamulira CNC Machining

Mphero ya CNC yokhala ndi mizere isanu imakhala ndi mbali ina yozungulira poyerekeza ndi CNC yamagulu anayi.Mzere wachisanu ndi kuzungulira mozungulira y-axis, yomwe imadziwikanso kuti b-axis.Chogwirira ntchito chimatha kuzunguliridwanso pamakina ena, omwe nthawi zina amatchedwa b-axis kapena c-axis.

Chifukwa cha kusinthasintha kwakukulu kwa 5-axis CNC Machining, imagwiritsidwa ntchito popanga magawo olondola kwambiri.Monga zigawo zachipatala za miyendo kapena mafupa ochita kupanga, mbali zakuthambo, mbali za titaniyamu, zida zamakina amafuta ndi gasi, zida zankhondo, ndi zina zambiri.

Nthawi yotumiza: Sep-29-2022