Ma Burrs ndi vuto lofala pakukonza zitsulo, monga kubowola, kutembenuza, mphero, ndi kudula zitsulo...

Chimodzi mwa zoopsa za ma burrs ndikuti ndi osavuta kudula!Kuchotsa ma burrs, ntchito yachiwiri yotchedwa deburring nthawi zambiri imafunika.3 kubweza ndi kumaliza m'mphepete mwa magawo olondola kumatha kuwerengera 30% ya mtengo wagawo lomalizidwa.Komanso, kumaliza ntchito zachiwiri kumakhala kovuta kupanga makina, kotero ma burrs amakhaladi vuto lachinyengo.

Momwe mungathetsereBURRS

1 Kuchotsera pamanja

Iyi ndi njira yodziwika bwino komanso yogwiritsidwa ntchito kwambiri, pogwiritsa ntchito mafayilo (mafayilo amanja ndi mafayilo a pneumatic), sandpaper, sanders lamba, mitu yopera, ndi zina zotero monga zida zothandizira.

Zoyipanma tages: Mtengo wa ntchito ndi wokwera mtengo, kuyendetsa bwino sikokwera kwambiri, ndipo n'zovuta kuchotsa mabowo ovuta.

Zinthu zogwiritsidwa ntchito: Zofunikira zaukadaulo kwa ogwira ntchito sizokwera kwambiri, ndipo ndizoyenera zopangira ma aluminiyamu alloy die castings okhala ndi ma burrs ang'onoang'ono komanso mawonekedwe osavuta azinthu.

2 Kufa kwamphamvu

Kudulira kumachitika pogwiritsa ntchito ufa wopangira ndi nkhonya.

Zoipa: Zimafunika mtengo wochuluka wa kufa (kufa movutikira, kufa bwino) mtengo wopangira, ndipo zingafunikirenso kupanga kufa kwa mawonekedwe.

Zinthu zomwe zingagwiritsidwe ntchito: Ndizoyenera kuyika ma aluminiyumu aloyi kufa ndi malo osavuta olekanitsa, ndipo magwiridwe antchito ndi kuwononga ndizabwinoko kuposa ntchito zamanja.

3 Kuwotcha ndi kuwotcha

Kuwonongeka kwamtunduwu kumaphatikizapo kugwedezeka, sandblasting, rollers, ndi zina zotero, ndipo panopa amagwiritsidwa ntchito ndi zomera zowonongeka.

Zoipa: Pali vuto loti kuchotsako sikuli koyera kwambiri, ndipo kukonzanso kwamanja kwa ma burrs otsalira kapena njira zina zochotsera zingafunikire.

Zinthu zogwiritsidwa ntchito: zoyenera zopangira zing'onozing'ono za aluminium alloy die castings ndi magulu akulu.

4 Kutentha kozizira

Gwiritsani ntchito kuziziritsa kuti muchepetse ma burrs mwachangu, kenako tsitsani ma projectiles kuti muchotse ma burrs.Mtengo wa zida ndi za 200,000 kapena 300,000;

Zinthu zomwe zingagwiritsidwe ntchito: Zoyenera kuyika ma aluminiyamu alloy die castings okhala ndi makulidwe ang'onoang'ono a khoma ndi voliyumu yaying'ono.

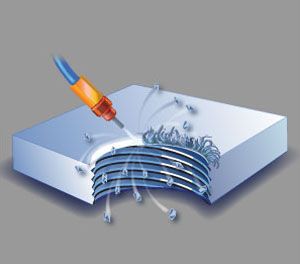

5 Kutentha kwamoto kuphulika

Kumatchedwanso thermal deburring, explosion deburring.Poyambitsa gasi wina woyaka moto mu ng'anjo ya zida, ndiyeno kudzera muzochita zamtundu wina ndi zikhalidwe, mpweya umaphulika nthawi yomweyo, ndipo mphamvu yopangidwa ndi kuphulikako imagwiritsidwa ntchito kusungunula ndikuchotsa burr.

Zoipa: zida zamtengo wapatali (mamiliyoni a madola), zofunikira zamakono zogwirira ntchito, kuchepa kwachangu, zotsatira zoyipa (kudzimbirira, kupunduka);

Zinthu zomwe zingagwiritsidwe ntchito: Zomwe zimagwiritsidwa ntchito makamaka m'magawo ena olondola kwambiri, monga magalimoto ndi malo oyendetsa ndege.

6 Kusintha kwa makina osindikizira

Mtengo wa zida siwokwera mtengo kwambiri (makumi masauzande).

Zinthu zogwiritsidwa ntchito: Ndizoyenera kupanga malo osavuta komanso malo osavuta komanso okhazikika.

7 Kuchotsa Chemical

Pogwiritsa ntchito mfundo ya electrochemical reaction, magawo opangidwa ndi zitsulo amatha kusinthidwa mosankha.

Zinthu zogwiritsidwa ntchito: zoyenerera ma burrs amkati omwe ndi ovuta kuchotsa, oyenera ma burrs ang'onoang'ono (mawaya osakwana 7) azinthu monga matupi a pampu ndi ma valve.

8 Electrolytic deburring

Njira yopangira ma electrolytic pakuchotsa ma aluminium alloy die-casting burrs ndi electrolysis.Electrolytic deburring ndiyoyenera kuchotsa ma burrs m'malo obisika a aluminiyamu alloy die castings, mabowo opingasa kapena magawo okhala ndi mawonekedwe ovuta.Kuchita bwino kwa kupanga ndikwambiri, ndipo nthawi yochotsa nthawi zambiri imakhala masekondi angapo mpaka makumi amasekondi.

Zoipa: Elekitiroliyi imawononga kumlingo wakutiwakuti, ndipo pafupi ndi burr ya ziwalozo imayikidwanso ndi electrolysis, pamwamba idzataya kuwala kwake koyambirira, ndipo ngakhale kukhudza kulondola kwa dimensional.Chitsulo cha aluminiyamu chakufa chiyenera kutsukidwa ndi kutetezedwa ndi dzimbiri pambuyo pochotsa.

Zinthu zogwiritsidwa ntchito: Ndioyenera kuthamangitsa magiya, ndodo zolumikizira, ma valve ndi mabowo odutsa mafuta a crankshaft, komanso kuzungulira ngodya zakuthwa.

9 Kuwotcha kwamadzi othamanga kwambiri

Pogwiritsa ntchito madzi ngati sing'anga, imatha kugwiritsa ntchito mphamvu yake yanthawi yomweyo kuchotsa ma burrs ndi kuwala kopangidwa pambuyo pokonza, ndipo nthawi yomweyo, imatha kukwaniritsa cholinga choyeretsa.

Zoipa: Zida zodula

Zinthu zogwiritsidwa ntchito: zomwe zimagwiritsidwa ntchito makamaka pamtima wamagalimoto ndi makina owongolera ma hydraulic pamakina omanga.

10 Ultrasonic deburring

Kugwedera kokhazikika kumakhala kovuta kuthana ndi ma burrs monga mabowo.Njira yopangira ma abrasive flow machining (njira ziwiri) imakankhira abrasive kupyola masilinda awiri opingasa abrasive kuti iziyenda uku ndi uku mu kanjira kopangidwa ndi chogwirira ntchito ndi cholumikizira.Kulowa ndi kutuluka kwa abrasive mkati ndi kupyola malo aliwonse omwe ali oletsedwa kumatulutsa zotsatira zowononga.Kuthamanga kwa extrusion kumayendetsedwa pa 7-200bar (100-3000 psi), yoyenera kukwapula kosiyana ndi nthawi zosiyanasiyana zozungulira.

Zinthu zogwiritsidwa ntchito: Imatha kunyamula ma 0.35mm microporous burrs, palibe ma burrs achiwiri omwe amapangidwa, ndipo mawonekedwe amadzimadzi amatha kuthana ndi ma burrs ovuta.

11 Abrasive flow deburing

Kugwedera kokhazikika kumakhala kovuta kuthana ndi ma burrs monga mabowo.Njira yopangira ma abrasive flow machining (njira ziwiri) imakankhira abrasive kupyola masilinda awiri opingasa abrasive kuti iziyenda uku ndi uku mu kanjira kopangidwa ndi chogwirira ntchito ndi cholumikizira.Kulowa ndi kutuluka kwa abrasive mkati ndi kupyola malo aliwonse omwe ali oletsedwa kumatulutsa zotsatira zowononga.Kuthamanga kwa extrusion kumayendetsedwa pa 7-200bar (100-3000 psi), yoyenera kukwapula kosiyana ndi nthawi zosiyanasiyana zozungulira.

Zinthu zogwiritsidwa ntchito: Imatha kunyamula ma 0.35mm microporous burrs, palibe ma burrs achiwiri omwe amapangidwa, ndipo mawonekedwe amadzimadzi amatha kuthana ndi ma burrs ovuta.

12 Kuwonongeka kwa maginito

Kugaya kwa maginito ndikuti pansi pa mphamvu ya maginito yamphamvu, maginito abrasives odzazidwa ndi maginito amakonzedwa motsatira njira ya maginito, adsorbed pamitengo ya maginito kuti apange "maburashi abrasive", ndikupanga kukakamiza kwina. pamwamba pa workpiece, ndi mitengo maginito akuyendetsa "abrasives".Pamene burashi ikuzungulira, imasunga kusiyana kwina ndikuyenda pamwamba pa workpiece, kuti azindikire kutha kwa pamwamba pa workpiece.

Features: otsika mtengo, lonse processing osiyanasiyana, ntchito yabwino

Zinthu zopangira: grindstone, mphamvu ya maginito, liwiro la workpiece, etc.

13 Malo opangira ma robot

Mfundoyi ndi yofanana ndi kubowola pamanja, kupatula kuti mphamvuyo imasinthidwa kukhala loboti.Mothandizidwa ndi ukadaulo wamapulogalamu ndi ukadaulo wowongolera mphamvu, kugaya kosinthika (kusintha kwa kuthamanga ndi liwiro) kumakwaniritsidwa, ndipo zabwino za kuwononga ma robot ndizowoneka bwino.

Poyerekeza ndi anthu, maloboti ali ndi mawonekedwe: kuwongolera bwino, kuwongolera bwino, komanso kukwera mtengo

Burrs mu Special Challenge Milled Parts

M'zigawo zogayidwa, kudula kumakhala kovuta kwambiri komanso kokwera mtengo, chifukwa ma burrs angapo amapangidwa m'malo osiyanasiyana amitundu yosiyanasiyana.Apa ndipamene kusankha njira zoyenera kuti muchepetse kukula kwa burr kumakhala kofunika kwambiri.

Nthawi yotumiza: Sep-29-2022